How to apply Loctite 638

Published date: 06 August 2021

Instructions on how to apply the Loctite 638 Retaining Compound.

1. Preparation

Cleaning

- Use LOCTITE 7200 for easier removal of residues in case of old retaining adhesive

- It is recommended to use LOCTITE 7063 to degrease and clean surfaces prior to applying the adhesive

- For gaps larger than 0.5mm or worn out shafts, bearing seats or keyways, use LOCTITE metal-filled compounds

Activation

If cure speed is too slow due to passive metals or low temperature (below 5°C), use activator LOCTITE 7240 or LOCTITE 7649 (see cure speed vs activator graph in the TDS).

2. Application

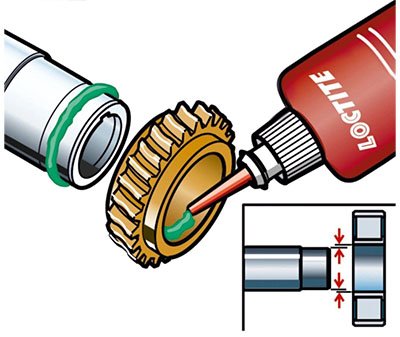

For slip fitted assemblies

Apply adhesive around the leading edge of the male component and the inside of the female component and use a rotating motion during assembly to ensure good coverage.

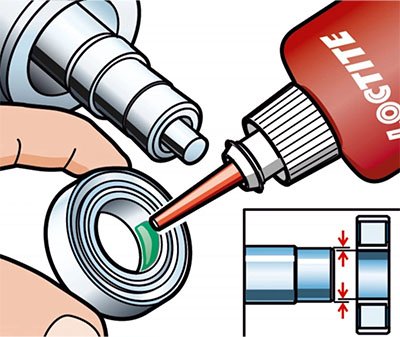

For press fitted assemblies.

Apply adhesive thoroughly to both bond surfaces and assemble at high press on rates.

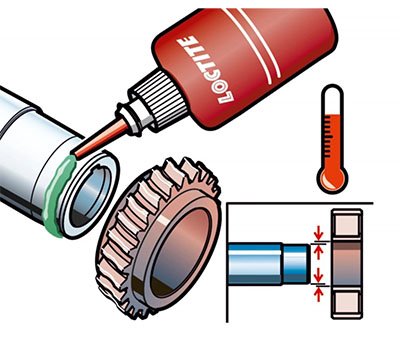

For shrink fitted assemblies.

Apply the adhesive onto the shaft, heat the collar to create enough clearance for free assembly.

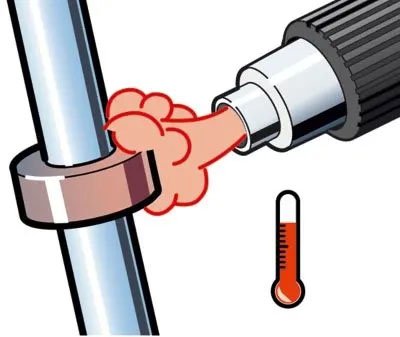

3. Disassembly

- Apply localised heat to approximately 250°c, disassemble while hot

- For corroded or seized parts, use LOCTITE 8040 Freeze and Release.

ConRo Electronics, is an authorised distributor for Henkel Loctite and seller of Loctite 638.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.