What is epoxy resin?

Published date: 14 September 2021

Epoxy resin is a multipurpose material with a wide range of applications. In this article we will see how it is created, what it is used for and its main advantages and disadvantages.

How does epoxy resin work?

Epoxy resin is created by mixing two components matched to each other: the liquid resin itself and a suitable hardener or “curative”. After the components have been mixed, the material is converted from a liquid to a solid (or “cured”) state. This process takes a variable amount of time, depending on the type of resin and the temperature at which it undergoes the hardening process.

The reaction of epoxy resin with hardeners generates a durable polymer with excellent adhesion properties, very good insulating properties and high thermal and chemical resistance.

What is epoxy resin used for?

Epoxy resin is very versatile and it can be used with a wide range of materials (including wood, metal, glass, fabric and stone) and for many different purposes.

One of the most common uses is for adhesive purposes. Epoxy resin is a high-performance adhesive, often used in the construction of aircrafts, boats, skies, snowboards and bicycles. It can also be used for arts and crafts projects and to repair fragile items made of glass, ceramic and china.

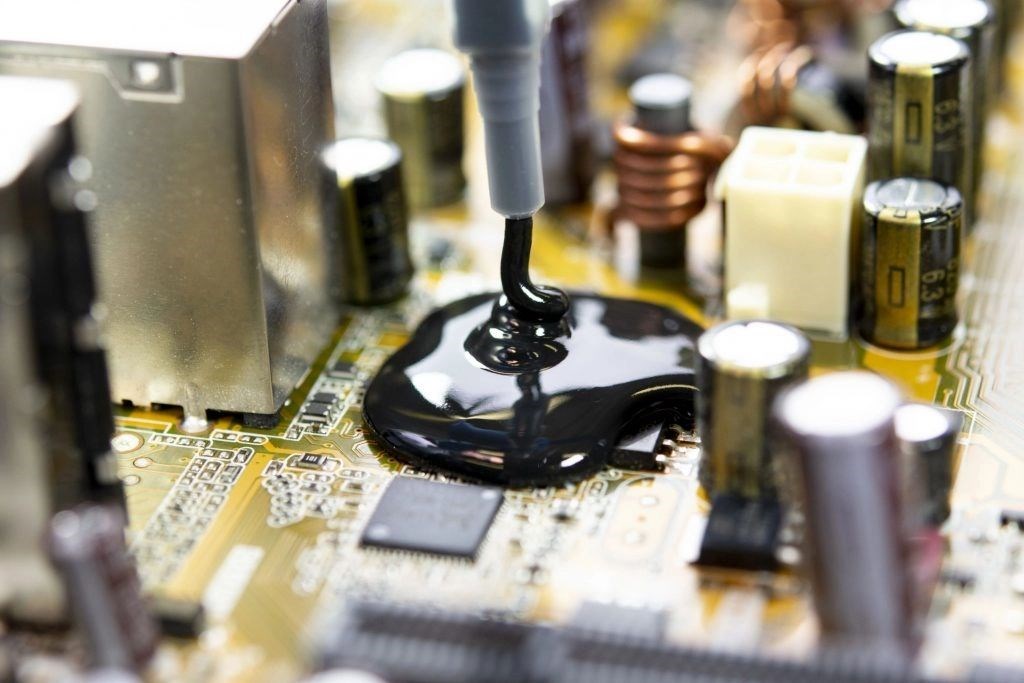

Epoxy resins are used in the electronic industry, thanks to their excellent electrical insulating properties. They are the primary resin used for integrated circuits, transistors and printed circuits boards.Epoxy paints and coating are often used on a metal substrate (such as cast iron, aluminium or steel), providing a durable protective coating. Epoxy resin is also known for its corrosion prevention properties, making it an ideal solution to many household objects like dryers, washers and other white goods, which may normally rust with time.

What are the advantages of epoxy resin?

Almost all epoxy resins share the same advantages: high material strength, resistance to shattering, splintering and abrasion, excellent adherence to most materials, high heat resistance and non-flammability, resistance to acid and corrosion and strong insulating properties.

Almost all epoxy resins share the same advantages:

- High material strength.

- Resistance to shattering, splintering and abrasion.

- Excellent adherence to most materials.

- High heat resistance and non-flammability.

- Resistance to acid and corrosion.

- Strong insulating properties.

What are the disadvantages of epoxy resin?

Positive properties of epoxy resins outweigh the disadvantages, but there are some negative aspects to this material. Change in color, known as yellowing, is a common phenomenon for some epoxy materials, even when not exposed to UV radiation. Also, epoxy resin is not completely resistant to high-concentration acids.

Epoxy resins and their curing agents are skin irritants and may cause breathing difficulties. Contact with epoxy resins should only be made using gloves and face coverings and while working in well-ventilated areas.

Epoxy resin brands and products

Conro Electronics, as an electronic manufacturing and adhesives distributor, offers a wide choice of epoxy resins from major manufacturers such as Henkel Loctite and 3M.

ConRo Electronics is an authorised distributor for Henkel Loctite.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.