What does ESD stand for?

Published date: 11 May 2022

ESD is an acronym for electrostatic discharge. The term describes a swift flow of current between two electrically charged objects. It is often caused by a build-up of static electricity. The electricity is then released when two objects come in contact or proximity.

The magnitude of an ESD can vary widely. It ranges from the small shock we receive when we touch metal after walking on a carpet, to the millions of volts of a lightning strike.

What are the dangers of ESD?

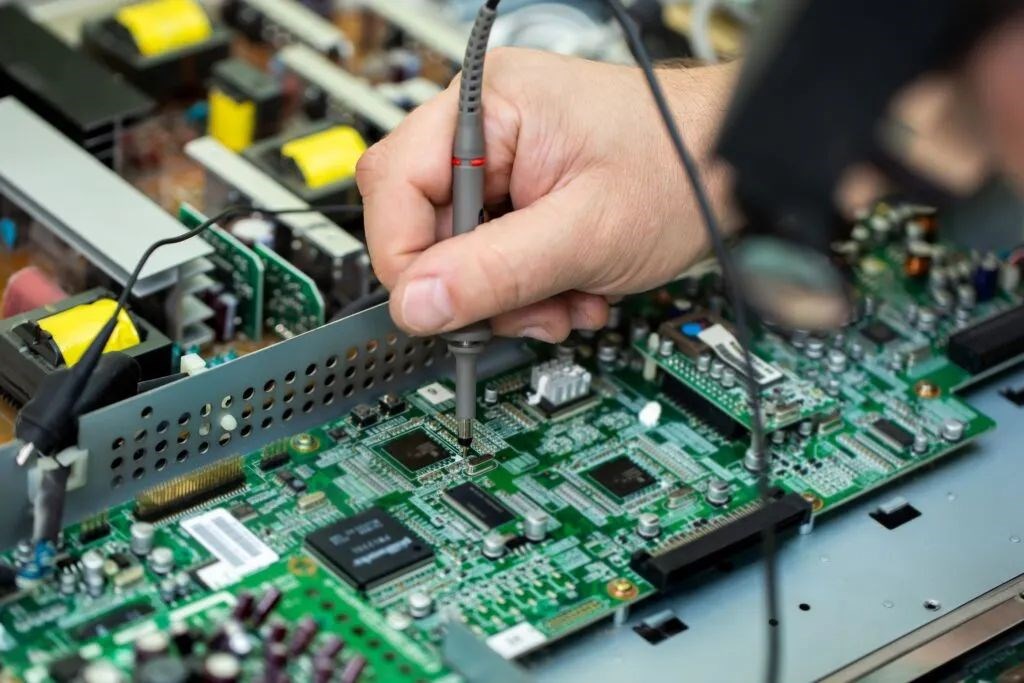

ESD is usually not harmful to the human body. However, it can cause extensive damage to electronics. Integrated circuit microchips are especially vulnerable to ESD. Discharge of electricity can cause circuits to melt or burn. As a result, a device could malfunction and become useless. This is known as catastrophic failure.

The damage caused by ESD to electronics may occur on a smaller scale. It may even go unnoticed at first. In this case, it is known as latent defect. Latent defects are, potentially, even more damaging than a complete device failure. They are very hard to identify before the device is released for use. Latent defects significantly shorten the life of a device and are expensive to repair.

It is worth adding that sparks caused by ESD are a serious fire hazard. A single spark can be a source of ignition in combustible environments. This can cause explosions where gas, fuel vapours or coal dust are present.

ESD prevention

To prevent ESD, procedures should be followed to reduce or eliminate static electricity. These measures should cover the manufacturing, testing, shipping, and handling processes.

Useful ESD prevention measures include:

- Using monitoring equipment. Devices capable of detecting and measuring ESD events.

- Workers can use anti-static wrist straps. They are attached to a ground conductor and safely ground static electricity. Other solutions include anti-static floor mats.

- Reducing humidity. Dehumidifiers make the work environment drier, decreasing the likelihood of ESD happening.

- Using anti-static packaging. Anti-static bags protect electronic components from static during shipping.

It is important to make workers aware of the dangers posed by static discharge. ESD control areas can be set up in the workplace. In these areas, the need to control ESD can be further highlighted. Signs can be put up to this purpose.

By increasing ESD awareness and adopting preventive measures, manufactures can reduce the possibility of electrostatic damage. This, in turn, will avoid waste, increased costs and damage to the company’s reputation.

Conro Electronics is a leading supplier of materials and tools in the electronic manufacturing industry.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.