What Are Structural Adhesives?

Published date: 17 March 2021

Structural adhesives are formulated to provide tough, durable bonds to a wide variety of surfaces.

They have been built to meet the increasing demands for assembly design and maintenance repair for:

- Structural bonding with high efficiency

- Bonding on different surfaces of a structure

- Bonding of structurally dissimilar substrates

- Structural adhesives with low threat

Most of the structural adhesives come in convenient packets for hand-held, manual, and semi-automated applications, such as cartridges, syringes, soft-squeeze bottles, and dual cartridges for two-part formulations. For high-volume dispensing and automated assembly processes, these are also available in larger packages of 20 litre or 200 litre.

Structural adhesive types

There are several structural adhesives on the market today that meet a wide variety of industrial and commercial design requirements. Each has distinct advantages, allowing you to customise your adhesive selection based on how its features meet the requirements of your particular application.

Both Loctite and Teroson brands are designed to provide versatility and adaptability to a wide variety of applications, with each product appropriate for bonding substrates, including dissimilar substrates, with unique characteristics that meet your requirements. The 3 main types are:

- Epoxy

- Acrylic

- Polyurethane

Industrial Applications for Structural Adhesives

Structural adhesives are well suited to an incredibly wide range of applications and are most widely used in the automotive, aerospace, electronics, manufacturing, engineered wood, medical, and consumer industries. They are used in a variety of applications, including magnet bonding, metal bonding, multiple surface bonding, NVH – noise, vibration, and harshness reduction, plastic and composite bonding, and potting and encapsulating.

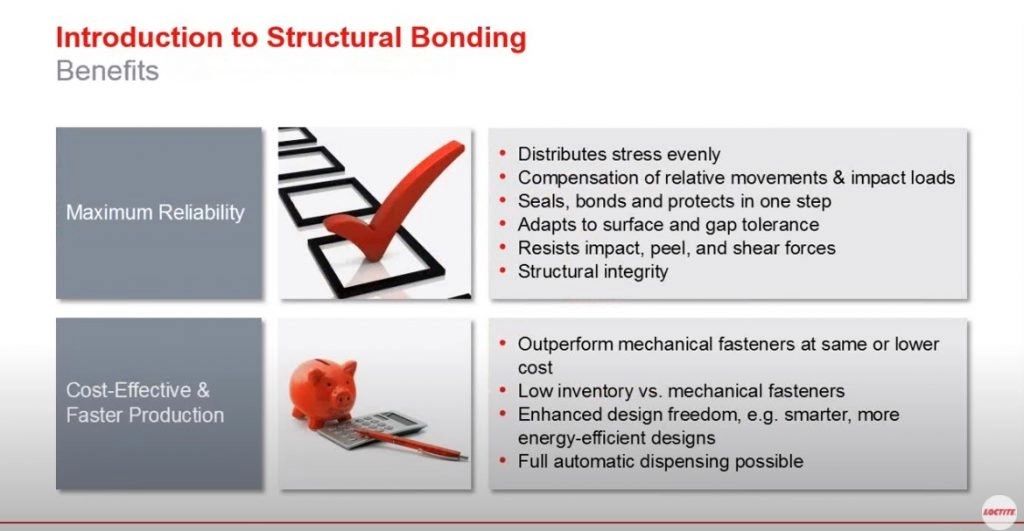

Features:

- Elimination or significant reduction of costly mechanical fastening methods

- Improved aesthetics compared to mechanical fasteners

- Fast processing speeds

- Reduction in labour costs

- Filling of large gaps between parts

- User-friendly packaging

For more details and visual presentation watch this webinar by Loctite.

If you have any questions regarding structural adhesives and Loctite products feel free to contact us.

Source: loctite.com

Comments

There are currently no comments, be the first to comment.