How to clean electronic circuit boards?

Published date: 26 January 2022

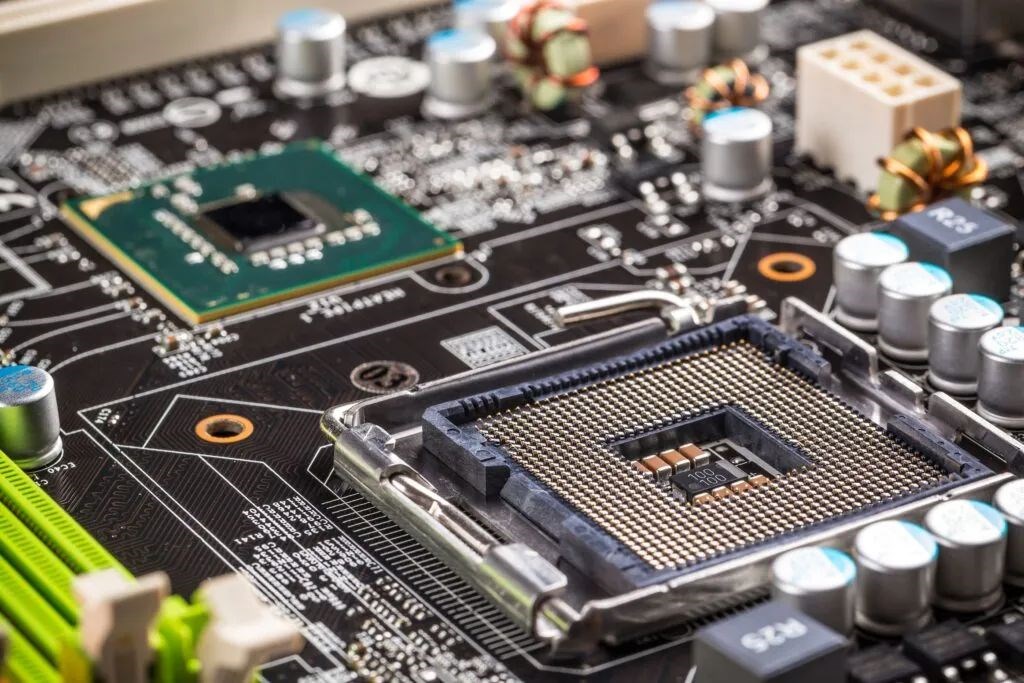

Electronic circuit boards can be exposed to a wide variety of contaminants during use. Cleaning them is a delicate process. Components and connections can easily be damaged if the board is handled improperly. Make sure you understand how to disassemble and reassemble a device before starting.

How to clean electronic circuit boards depends on the types of contaminants you are dealing with. Dust and dirt can be cleaned with a brush or with compressed air. Minor grime can be removed with a solvent. Significant corrosion, however, should be treated with baking soda.

Always be careful during the cleaning process. Disconnect the device from its power source first. Avoid standing near water and wear dry clothes.

How to clean dust from circuit boards

Dirt or dust can slow down a circuit board or even make it unusable. There are two main ways to clean dry contamination:

- Brushing: Use a small, delicate brush to remove dirt and dust. A horsehair paintbrush is especially well-suited to the task.

- Compressed Air: Spray compressed air in short bursts onto the board. Keep the canister upright and the nozzle a few centimeters away from the components.

Compressed air is potentially damaging to electronic connections. You should not use this method regularly.

How to clean grime from circuit boards

Grime, flux or oil can create a sticky film on a circuit board. This is problem in itself, and it can also lead to more contamination by dust and dirt. There are a few ways to clean wet contaminants:

- Isopropyl alcohol: Dip a cotton swab in 90%-100% alcohol. Make sure the swab is only lightly damp. Brush the cotton swab across the grime to dislodge it. Don’t be too forceful. When you’re finished, allow the alcohol to dry.

- Demineralised water: You can swab the board with demineralised water instead of alcohol. Use only the smallest amount of water. Make sure to thoroughly dry the PCB before use.

- Specialty cleaning agents: You can use PCB cleaning agents tailored toward specific contaminants. Make sure the cleaner you are using is not too harsh. You may want to test a product on an old board first.

How to clean corrosion from circuit boards

Corrosion on circuit boards is usually caused by exposure to moisture or acid leaks from batteries. Corrosion might be too difficult to clean with alcohol or another solvent. If nothing else works, use baking soda.

Mix together baking soda and some water in a bowl until they form a runny paste. Soak a cotton swab in the mixture. Apply it gently to the corroded areas of your PCB, until they are fully covered.

Wait for the paste to dry on the circuit board. This usually takes 24 hours. Then, dampen a cotton swab with isopropyl alcohol. Use the swab to lightly brush away the dried paste and corrosion.

Conro Electronics offers a wide choice of cleaning solutions for electronics, from major manufacturers such as Ambersil, Microcare and Inventec.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.