Die Attach Adhesives – Sustainability and Environmental Considerations

Published date: 12 February 2024

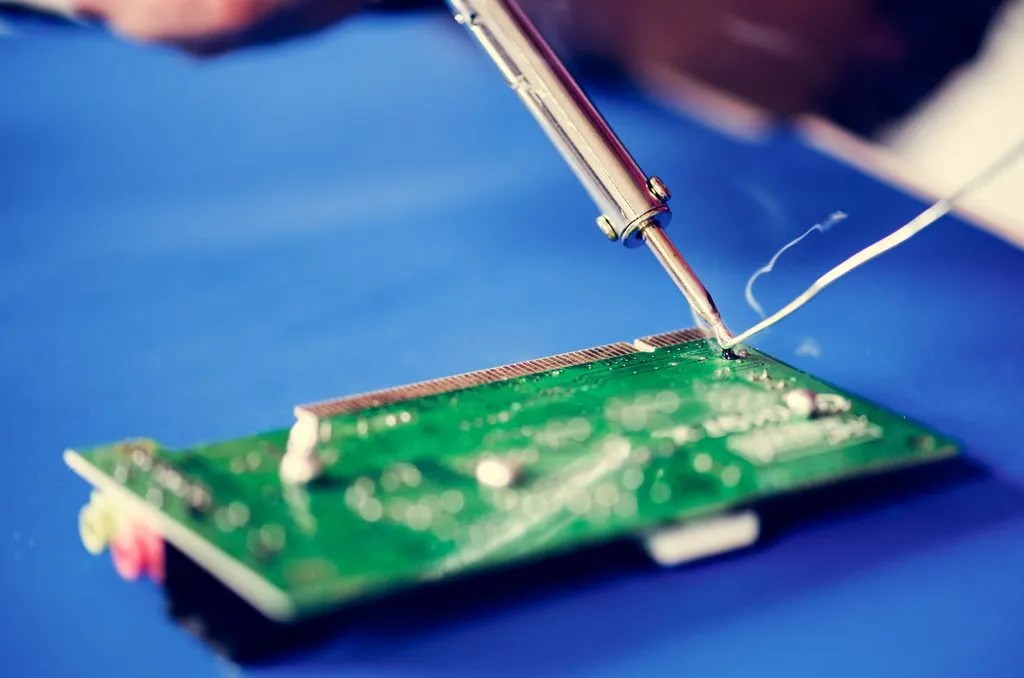

Growing environmental concerns, coupled with the impact of European legislation curbing hazardous substance usage in electronics, have become a catalyst for innovation in materials. In the semiconductor manufacturing sector, die attach adhesives emerge as an eco-friendlier alternative to traditional lead-based solders. By employing polymer-based adhesives, typically epoxy resins, die attach adhesives offer an alternative with significant environmental benefits. This blog post delves into the reasons behind this transition and explores the environmental implications of semiconductor manufacturing processes.

Environmental Impact of Semiconductor Manufacturing Processes

Semiconductor manufacturing processes, while essential for technological advancement, have notable environmental implications. One significant concern is the generation of electronic waste (e-waste) resulting from the disposal of outdated or malfunctioning electronic devices. Lead-based solders, commonly used in die attach technologies in the past, pose significant risks to ecosystems and human health if not managed properly. Furthermore, the energy-intensive nature of semiconductor fabrication processes contributes to carbon emissions and resource depletion. The adoption of epoxy die attach adhesives brings forth several advantages in promoting sustainability within the semiconductor industry.

Epoxy Die Attach Adhesives: A Versatile Solution

Epoxy die attach adhesives function as two-part systems, comprising a resin and a hardener, mixed just before application. Once applied to the die or substrate, the mixture undergoes curing through heat, forming a robust bond. Epoxy adhesives provide lower thermal and electrical conductivities compared to lead alloys, compensating these drawbacks with their outstanding versatility. Epoxy adhesives can be formulated with a diverse range of properties, catering to various application requirements, thus offering flexibility without compromising performance.

Die Attach Adhesives and Sustainability

Die attach adhesives offer a more eco-friendly alternative to solders, primarily due to their composition and application. Unlike eutectic die attach solutions, adhesives typically contain no hazardous materials such as lead, making them safer for both the environment and human health. Many epoxy adhesives also exhibit low volatile organic compound (VOC) emissions, ensuring better air quality during application and throughout the product’s lifecycle.

Additionally, the application process of die attach adhesives often involves lower temperatures compared to soldering, reducing energy consumption and greenhouse gas emissions. The shift towards die attach adhesives aligns with global initiatives aimed at phasing out hazardous substances and promoting sustainable manufacturing practices across industries.

Evolving Towards Sustainability: Bio-Based Epoxy Resins

While epoxy resins are generally eco-friendlier than eutectic die attach methods, they are synthetically derived from petroleum, posing their own environmental concerns. Addressing the environmental footprint of epoxy resins necessitates exploring alternatives derived from renewable resources.

Bio-based epoxy resins, emerging as a promising development, offer a sustainable pathway forward for the adhesive industry. Derived from resources such as plants or agricultural waste, these eco-friendly alternatives mitigate environmental impact while maintaining performance standards. The future outlook for bio-based epoxy resins looks full of promise, representing a significant stride towards sustainable semiconductor manufacturing practices.

At Conro Electronics, we’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.