Die attach adhesives – Innovations and Trends

Published date: 21 April 2024

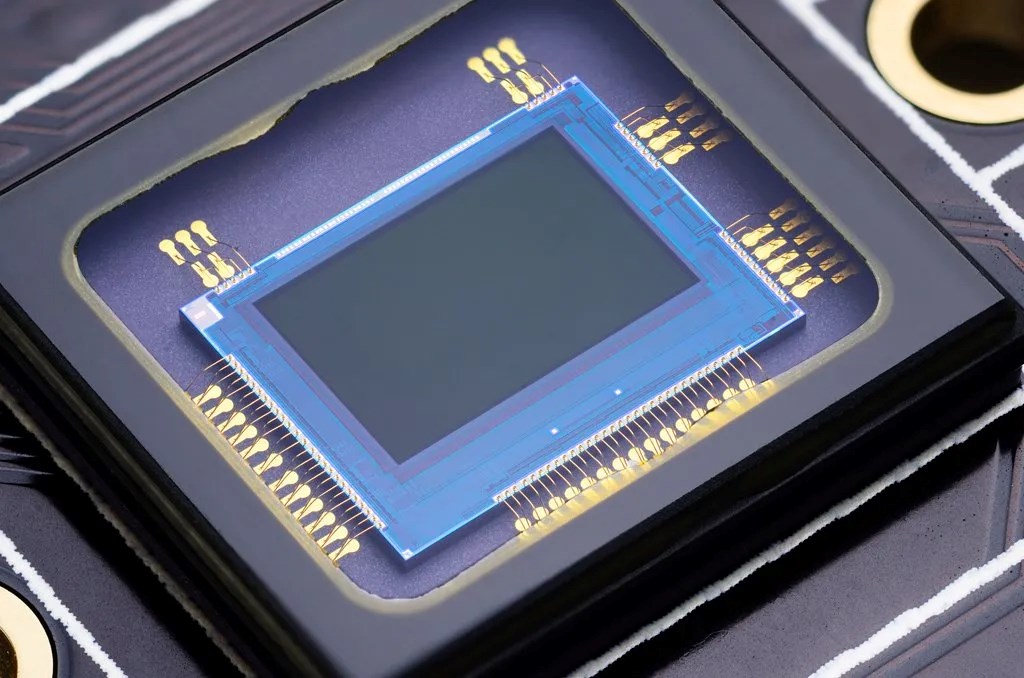

Die attach adhesives are witnessing a transformative phase of innovation and technological advancement. As the electronic industry evolves, demands for higher performance, sustainability, and reliability drive the development of novel adhesive materials and manufacturing processes. In this blog post, we delve into the latest trends and innovations shaping the landscape of die attach adhesives.

Enhanced Thermal Conductivity with Nano-fillers

One notable trend in die attach adhesive technology is the integration of nano-fillers to enhance thermal conductivity. Standard silver epoxy pastes are a reliable form of adhesive, but their thermal properties are inadequate for certain devices. Moreover, the miniaturization of electronic devices drives a pressing need for materials capable of efficient heat dissipation.

As a solution, nano-fillers, such as grapheme, nickel nanochain or carbon nanotubes, are being incorporated into die attach adhesives to improve thermal and/or electrical conductivity, ensuring optimal performance and reliability of electronic components. By facilitating better heat dissipation, these advanced adhesives contribute to the longevity and efficiency of electronic devices.

Environmental Sustainability

Growing environmental concerns and regulatory initiatives drive the adoption of eco-friendly and sustainable die attach adhesives. While epoxy-based adhesives are generally eco-friendlier than eutectic die attach methods, they are derived from petroleum, posing their own environmental concerns. Manufacturers are now steering towards materials with lower environmental impact and reduced volatile organic compound (VOC) emissions.

Bio-based polymers, derived from renewable resources like plants or agricultural waste, are emerging as promising alternatives to conventional epoxy resins. These sustainable adhesives not only meet regulatory requirements but also mitigate environmental impact while maintaining performance standards.

Conductive Adhesives

Advancements in die attach adhesive technology extend to new bonding techniques and assembly processes. Conductive adhesives, featuring silver micro-fillers and nano-fillers, are revolutionizing electronic assembly by eliminating the need for soldering or traditional epoxy-based die attach adhesives in specific applications. These conductive adhesives offer reliable electrical connections, particularly in flexible or temperature-sensitive substrates. Moreover, they enable lower processing temperatures, reducing thermal stress and enhancing compatibility with thin, lightweight electronic devices.

Reliability in Harsh Environments

The proliferation of electronics in automotive, aerospace, and industrial control systems necessitates adhesives with enhanced reliability in harsh operating conditions. Manufacturers are developing die attach adhesives resilient to temperature extremes, humidity, vibration, and chemical exposure, to ensure long-term performance and durability of electronic systems. New materials are designed to provide flexible curing conditions and improved rheological properties. These advanced adhesives guarantee strong adhesion to various substrate surfaces, even those with different coefficients of thermal expansion, finding their use in applications where reliability is paramount.

At Conro Electronics, we’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.