Die Attach Adhesives – Challenges and Solutions

Published date: 26 March 2024

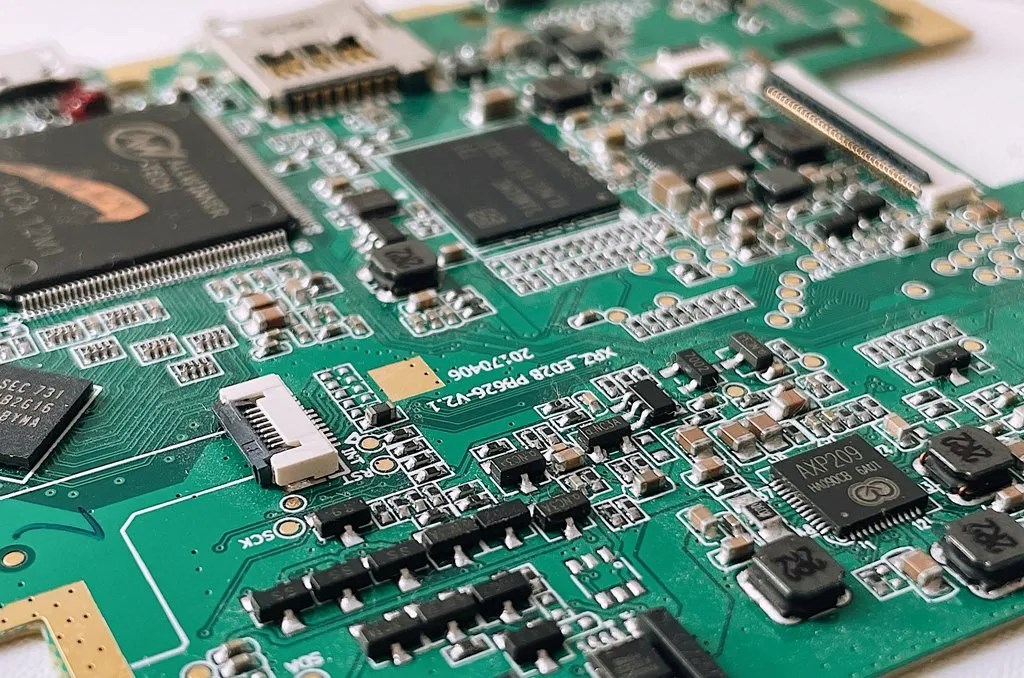

Die attach adhesives play a crucial role in semiconductor packaging, providing the necessary bond between the semiconductor die and its substrate and offering a versatile alternative to eutectic bonding. However, the die attach process comes with its set of challenges, which can impact the reliability and performance of the packaged device. In this article, we’ll delve into these common challenges and explore effective solutions and best practices to overcome them.

Understanding Common Challenges

There are several challenges that can undermine die attach processes and compromise the functionality and longevity of semiconductor devices. Void formation, delamination, and cracking stand out as the primary failure modes in this regard.

- Void Formation: One of the most common challenges in die attach processes is the formation of voids within the adhesive material. These voids, often caused by trapped gases or moisture during the dispensing or curing stages, pose a significant threat to device performance. They impede heat transfer, leading to thermal issues that can escalate to device failure. This is especially true for high-power applications, where efficient heat dissipation is paramount.

- Delamination: Delamination (or die lifting), the separation of the die from the substrate or the adhesive layer from either surface, is another critical challenge. Delamination can occur due to various factors, including inadequate surface preparation, mismatched coefficients of thermal expansion (CTE) between the die, substrate, and adhesive, or excessive mechanical stress during operation. Delamination not only compromises the electrical and thermal performance but also jeopardizes the long-term reliability of the packaged device.

- Cracking: Thermal or mechanical stresses can also lead to cracking within the die attach material, posing yet another threat to device integrity. These cracks propagate through the adhesive, compromising both electrical conductivity and heat dissipation. Even minute cracks can significantly impair device performance, highlighting the need to address this challenge effectively.

Solutions and Best Practices

- Material Selection: Choosing the right die attach adhesive goes a long way in overcoming challenges in the die attach process. It’s essential to select adhesives with properties tailored to the specific requirements of the application, including thermal conductivity, coefficient of thermal expansion, and adhesion strength. Conducting thorough material testing and qualification ensures that the selected adhesive meets the performance and reliability criteria of the packaged device.

- Dispensing Techniques: Optimising the adhesive dispensing process is essential to reduce void formation. Proper control of dispensing parameters such as pressure, temperature, and dispensing needle size can help minimise air entrapment and ensure uniform adhesive coverage.

- Curing Conditions: Proper curing conditions are vital to the integrity of the adhesive bond. Temperature, pressure, and curing time should be carefully controlled to achieve optimal adhesive properties. This, in turn, will minimise the risk of void formation and die lifting.

- Rigorous Quality Assessment: Implementing stringent quality control measures, such as non-destructive testing techniques like X-ray imaging and ultrasonic scanning, can help identify potential defects early in the production process. Adopting a proactive approach enables prompt intervention and rectification.

At Conro Electronics, we’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.