What is MEMS?

Published date: 15 March 2022

The acronym MEMS stands for Micro-Electro-Mechanical-System. It describes a miniaturised technology that has both mechanical and electronic components. The size of a MEMS can range from a few millimeters to less than one micrometer.

The term MEMS has evolved in meaning in the past years. MEMS defines both a category of devices and the processes used when manufacturing them. The main criterion of MEMS is the presence of mechanical elements. Whether or not these elements can move is secondary.

In Japan, MEMS are known as micromachines. In Europe, they are referred to as microsystems technology (MST). MEMS that convert a mechanical signal into an electric or optical signal are called transducers.

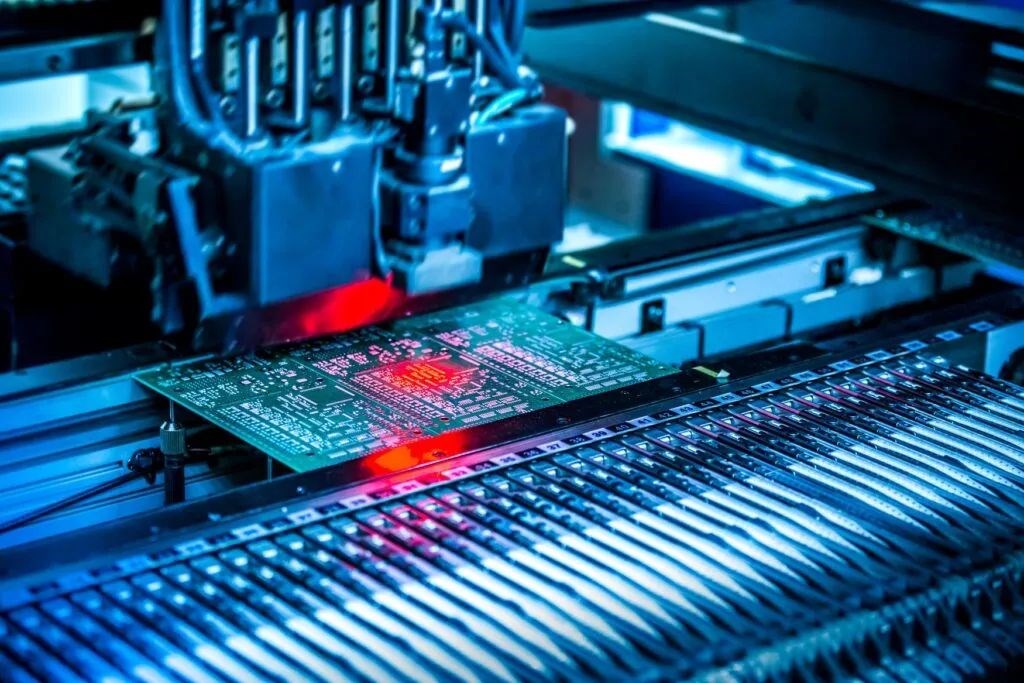

How are MEMS manufactured?

The fabrication of these systems evolved from the process of integrated-circuit manufacturing. Its basic steps are:

- Deposition of material layers

- Patterning by photolithography

- Etching to produce the required shapes

They are usually built from silicon. Layers of polycrystalline silicon are deposited on so-called “sacrificial” layers of silicon dioxide. After patterning and etching, the sacrificial layers dissolve. This reveals microscopic 3D structures such as wheels, gears and mirrors. Multiple systems can fit on a single wafer.

Various types of silicon wafers exist. They can possess varying levels of conductivity. Additional materials can be added to provide various features. Examples include electrode layers and piezoelectric layers.

What are the applications of MEMS?

The types of MEMS devices can vary greatly. They range from relatively simple structures with no moving parts, to complex electromechanical systems. Complex MEMS have multiple moving elements, under the control of integrated microelectronics.

MEMS are used in many different applications, including:

- Including accelerometers, gyroscopes, pressure and tilt sensors.

- Devices that convert electrical signals into action. Examples include switches and micro-pumps.

- Generators and energy sources. Including fuel cells, vibration energy harvesters and radioisotope power generators.

- Biochemical and biomedical systems. Including biosensors and air particulate sensors.

- For timekeeping and frequency control applications.

- Micro-mirror arrays. For high-definition projector systems.

- Inkjet printers. Using piezoelectrics or thermal bubble ejection to deposit ink on paper.

What are the main advantages of MEMS?

This technology offer several advantages:

- They are small in size and mass.

- They are scalable in manufacturing. Mass-producing results in low costs per unit.

- They require a low power consumption.

- They possess good thermal properties.

- They can be readily integrated into systems.

- MEMS sensors have a very high sensitivity.

- MEMS switches and actuators can attain very high frequencies.

Conro Electronics, is a leading supplier of materials and tools in the electronic manufacturing industry.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.