What’s the difference between stainless steel and carbon steel?

Published date: 27 February 2023

An overview of carbon and stainless steel

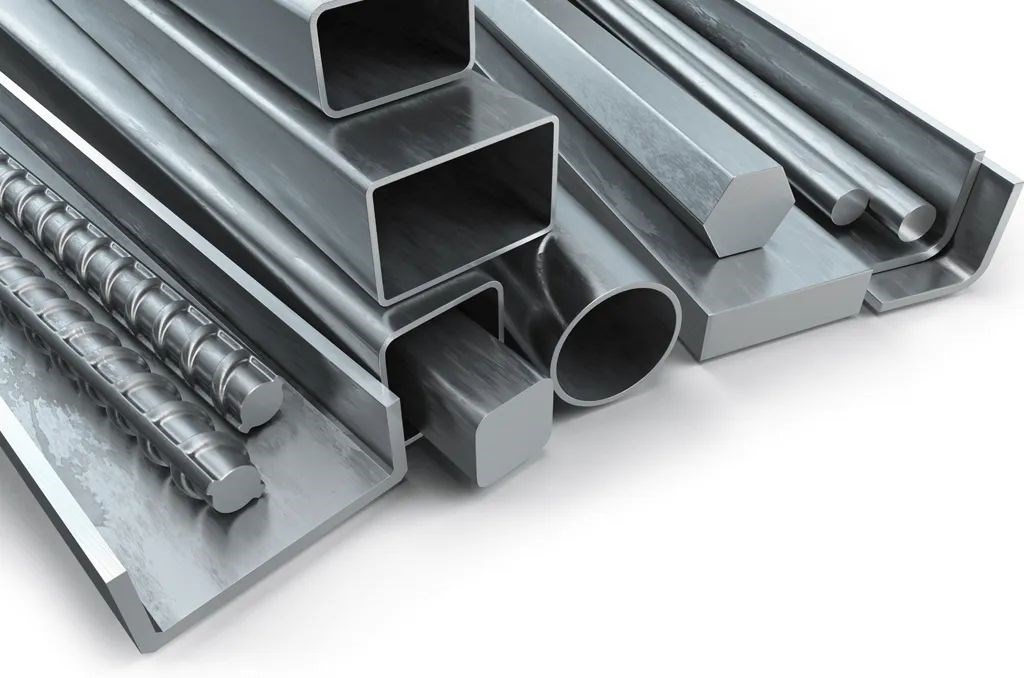

Steel is a strong alloy of iron and carbon that was first manufactured in 1800 BC. Today, steel is the most important engineering and construction material in the world. There are many different types of steel, each with its own unique properties and applications. Two of the most commonly used varieties are carbon steel and stainless steel.

The main difference between carbon and stainless steel is the alloy: carbon steel has less than 10.5% chromium content, while stainless steel has a chromium content equal to or greater than 10.5%. Both carbon and stainless steel are strong and durable materials, but they have some key differences.

What are the properties and applications of carbon steel?

Carbon steel is an alloy of iron, carbon (0.12-2.1%) and a limited amount of other alloying materials. The addition of carbon to the alloy makes it harder and stronger than iron alone. Carbon steel has an exceptionally wide range of applications, depending on the carbon content:

- Low-carbon steel: Automobile body components, pipes, construction and bridge components.

- Medium-carbon steel: Railway tracks, train wheels, gears and machinery parts.

- High-carbon steel: Cutting tools, springs, dies.

What are the properties and applications of stainless steel?

Stainless steel is an alloy of iron, less than 1.2% carbon and at least 10.5% chromium. The addition of chromium gives the alloy a shiny finish and makes it resistant to rusting and corrosion. The properties of stainless steel make it suitable for use in wet environments, as well as outdoor settings.

Stainless steel is often used for food-processing equipment, kitchen utensils, and medical instruments. It is also commonly employed in the aerospace and automotive industries.

Comparison between stainless steel and carbon steel

Here are the key differences between carbon steel and stainless steel:

- The main difference between the two varieties of steel is that stainless steel is resistant to corrosion, while carbon steel is not. Stainless steel contains chromium, which forms a thin protective layer on the surface of the steel upon contact with oxygen. Carbon steel, on the other hand, can be susceptible to rust if exposed to moisture or other corrosive elements.

- Chromium provides stainless steel with a shiny finish, while carbon steel has a less attractive appearance.

- Carbon steel is harder than stainless steel. This is due to its higher percentage of carbon. Carbon steel ideal for cutting tools, saws, and other equipment that needs to maintain a cutting edge. Stainless steel is less wear-resistant.

- Carbon steel, especially low-carbon steel, can be machined and welded more easily than stainless steel. Working with stainless steel is more difficult and time-consuming.

- Carbon steel is cheaper to mass produce compared to stainless steel.

- Stainless steel is lower maintenance, easier to clean material compared with carbon steel.

At Conro Electronics, we’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.