Die Attach Adhesives – Applications and a Case Study

Published date: 29 February 2024

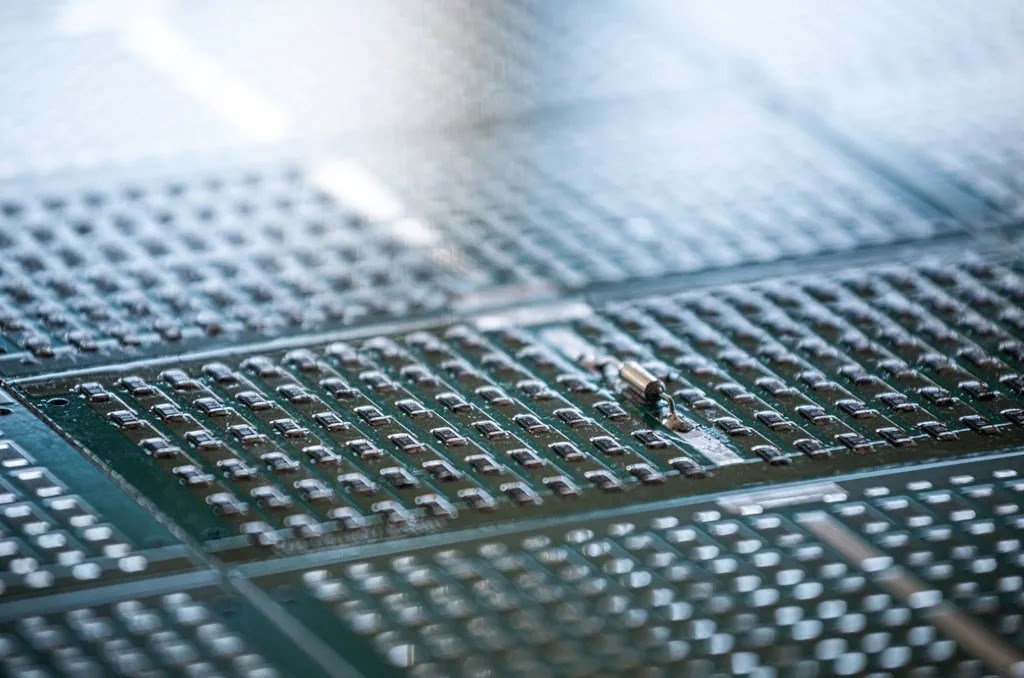

Die attach adhesives play a key role in microelectronics, offering a reliable alternative to eutectic die attach and facilitating the secure bonding of delicate components. These adhesives ensure mechanical stability and efficient thermal management, vital for the reliable performance of electronic devices across various industries. In this blog post, we delve into the wide-ranging applications of die attach adhesives and present a compelling case study showcasing their significance in a real-world scenario.

Industries Leveraging Die Attach Adhesives

Die attach adhesives and materials are indispensable in several industries, each benefiting from their unique properties and applications. These industries include:

- Electronics and Semiconductors: Within this sector, die attach adhesives are utilised for bonding microelectronic devices to their packaging substrates, ensuring the integrity and longevity of electronic assemblies.

- Automotive: Die attach adhesives play a crucial role in securely bonding electronic components to a vehicle’s electrical system, contributing to the efficiency and safety of modern automobiles.

- Medical: In the medical field, these adhesives are employed for attaching sensitive medical devices and sensors to patient monitoring systems, ensuring precise and reliable data collection.

- Aerospace: The aerospace industry relies on die attach adhesives to maintain the consistent and reliable performance of electronic systems in demanding environments, such as those encountered in aircrafts and spacecrafts.

- Telecommunications: Die attach adhesives enable the integration of electronic components in telecommunications equipment, ensuring optimal performance and reliability in communication networks.

- Consumer Electronics: From smartphones to smartwatches, die attach adhesives are essential for bonding electronic components in consumer devices, contributing to their compact design and robust functionality.

Factors like the development of advanced packaging techniques, the growing adoption of electric vehicles and wearable devices, and the demand for energy-efficient electronic devices, underscore the increasing importance and diffusion of die attach adhesives across these industries.

Case Study: Master Bond EP17HTDA-1 in Wearable Device Sensors

One exemplary application of die attach adhesives is showcased in the development of an air-microfluidic particulate matter sensor for wearable devices. Researchers from the University of Illinois at Chicago and the University of California, Berkeley, collaborated to design and fabricate a sensor aimed at monitoring user exposure to ambient particulate matter, which can pose significant health risks.

The sensor incorporated a complimentary metal-oxide semiconductor (CMOS) chip and a film bulk acoustic resonator (FBAR), both delicate components attached to silicon pedestals using Master Bond EP17HTDA-1 die attach adhesive. The silicon pedestals, measuring 1mm × 1mm x 0.5mm for the CMOS and 1mm × 1mm x 1mm for the FBAR, required precise and reliable bonding to ensure the sensor’s functionality.

Master Bond EP17HTDA-1 provided the researchers with the ideal viscosity flow profile for die attaching, crucial for bonding in very small areas. As a one-part heat-curing epoxy, it offered convenient application and processing, meeting the stringent requirements of the sensor assembly. Additionally, EP17HTDA-1 provided the necessary electrical insulation, thermal conductivity, and high die shear strength, ensuring the reliability and longevity of the sensor in wearable devices.

Click to shop die attach adhesives

At Conro Electronics, we’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.