- Home

- Adhesives

Adhesives

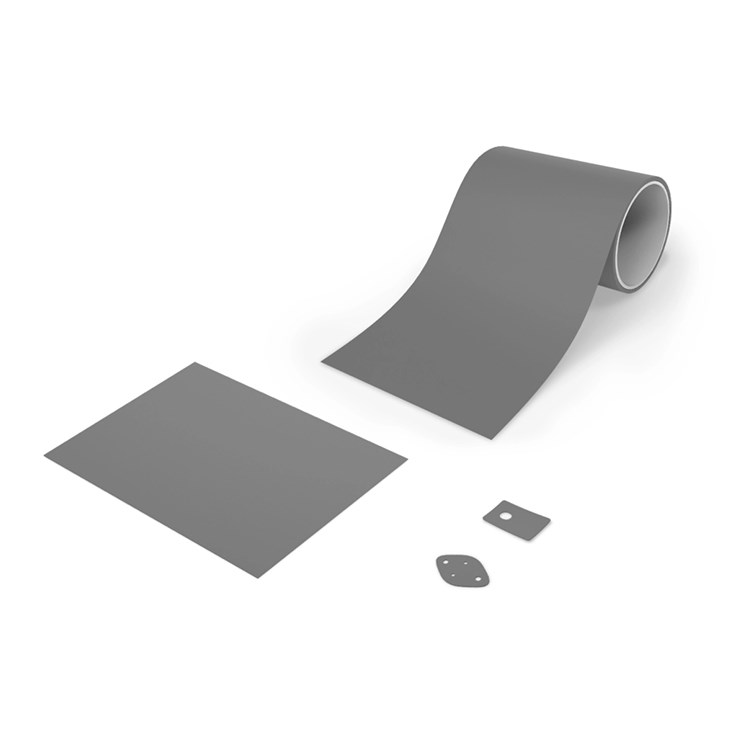

Explore ConRo's extensive range of adhesives, designed to meet the diverse needs of various industries. Our product offerings include contact adhesives, cyanoacrylate adhesives, die attach adhesives, and electrically conductive adhesives. We also provide encapsulants, epoxy adhesives, film adhesives, hot melt adhesives, hybrid adhesives, and instant adhesives for quick bonding solutions.

Our selection extends to MOD, phase change materials, potting compounds, retaining compounds, SMT adhesives, solvent-based adhesives, spray adhesives, structural adhesives, and surface preparation products. For thermal management, we offer thermal gap fillers, thermal gels, thermal sil pad materials, and thermally conductive adhesives. Additionally, our portfolio includes threadlockers, UV adhesives, water-based adhesives, and windscreen adhesives, ensuring you find the right solution for every application.

As an authorized distributor for trusted brands like Loctite, Henkel, Permabond, and Huntsman, ConRo guarantees high-quality products that adhere to rigorous industry standards. Whether you’re in manufacturing, automotive, or electronics, our adhesives deliver exceptional performance and reliability.

Adhesive bonding

Adhesive is used to join two surfaces, producing a smooth bond. This technique usually involves glues or epoxies that bond by drying.

The adhesive is applied in liquid form. This allows it to fill gaps and soak into the pores of the surfaces. When it cures and becomes solid, it holds the two objects together. Curing occurs with heat, pressure and/or time.

Advantages of using adhesives

Traditional joining procedures have several drawbacks. With welding, heat alters the specific properties of the materials. Mechanical techniques, such as riveting, distribute stress inefficiently. In addition, they can weaken the materials.

Today there are adhesives strong enough to replace rivets and welding. Using them has many advantages:

- Bonding almost any desired combination of materials

- Allowing the material properties of the substrates to be retained

- Saving time and accelerating the production process

- Removing unevenness on material surfaces

- Allowing for greater stress tolerance by filling gaps

- Preventing contact corrosion for metal bonds (the adhesive works as insulator)

Types of adhesives

There are many types for various applications. They may be classified in a variety of ways:

- By chemical composition: epoxies, polyurethanes, polyimides

- By physical form: paste, liquid, film, pellets

- By structure: hot melt, reactive hot melt, pressure sensitive, contact, etc.

- By load bearing capacity: structural, semi-structural, or non-structural