What is thermography and how does it work?

Published date: 29 March 2023

Thermography is a non-invasive imaging technique that uses infrared radiation to detect and measure temperature differences. This technology is commonly used in various fields, including a wide range of industries. In this blog post, we will explore what thermography is and how it works, highlighting its benefits and applications in industrial settings. So, let’s dive in!

How does thermography work?

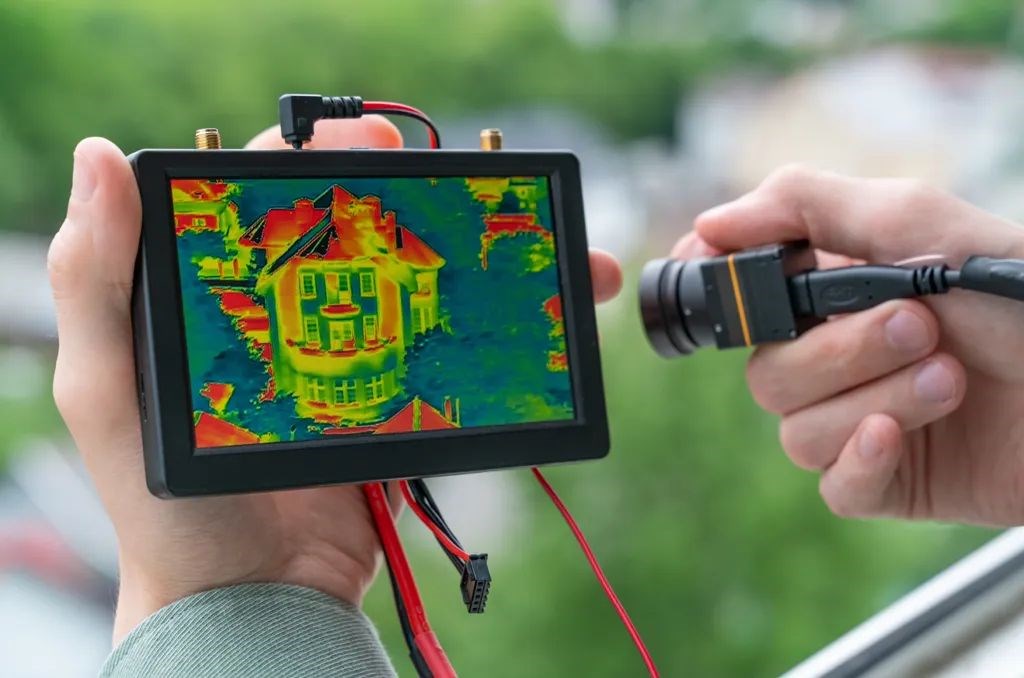

Thermography uses infrared radiation to detect and measure temperature differences on the surface of an object. The process involves using a thermographic camera, which is designed to capture infrared radiation. The camera detects the temperature of each pixel in its field of view and creates an image based on these temperature readings. The resulting image shows variations in temperature as different colours or shades.

Thermography is a powerful tool for identifying temperature anomalies and providing insight into potential issues that may not be visible through other imaging techniques. Its non-invasive nature makes it a safe and effective option for a wide range of applications.

What are the industrial applications of thermography?

Thermography can be used in a variety of industrial applications, including:

- Quality control and assurance: Thermography can be used to identify defects or anomalies in products or materials, such as overheating bearings. This can be particularly useful in industries such as aerospace, automotive, and manufacturing.

- Energy efficiency: Thermography can be used to identify areas of excessive heat generation or loss. This can help improve energy efficiency and reduce costs.

- HVAC system diagnostics: Thermography can be used to diagnose problems with heating, ventilation, and air conditioning (HVAC) systems, leading to improved system efficiency.

- Paved surfaces inspection: Thermography can be used to detect cracks and discontinuities in paved surfaces. Any air or water penetrating these discontinuities has an effect on thermal transmission, so it is can be detected with a heat-sensing device.

Advantages and limitations of thermography

Thermography provides several advantages over other testing techniques:

- Non-invasive: Thermography can be used to inspect equipment and materials without causing damage. This is particularly important in industries such as aerospace, where critical components must be inspected regularly without causing any damage to them.

- Accurate: Thermography accurately represents temperatures by colour coding. This allows to clearly identify the exact location of any problems and anomalies.

- Fast: Thermography works in real time, allowing to quickly identify potential problems. By recognising temperature anomalies early on, companies can avoid costly downtime and repairs.

However, there are also some limitations to thermography, including:

- Surface level: Thermography is only effective at detecting surface-level temperature differences. If a problem is occurring within the interior of a material or component, thermography may not be able to detect it.

- Cost: Thermography requires specialised equipment and trained personnel to operate it effectively. This means that it can be expensive to implement, particularly for smaller companies.

Despite its limitations, the advantages of thermography make it a valuable tool for many industries. By providing a non-destructive way to quickly and accurately detect potential problems, it can help companies to improve their processes and increase efficiency while minimising downtime and costs.

At Conro Electronics, we’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.