Sustainable Conformal Coatings – Green PCB Protection

Published date: 13 May 2021

Conformal coatings became popular for protecting printed circuit boards (PCBs) about five decades ago. Early PCB failures caused by dust and soil, liquids, and humidity contamination were significantly reduced or eliminated as a result of their use. As a result, longer warranties and better reliability are now possible. Many early conformal coatings, many of which are still in use today, were made from polymers dissolved in solvents such as MEK, toluene, or xylene.

A rough evolution of conformal coating chemistries may be seen as

- Solvent-based acrylics and polyurethanes

- Water-based acrylics

- Synthetic rubber coatings

- UV-curable acrylate urethanes

- LED UV-curable acrylate urethanes

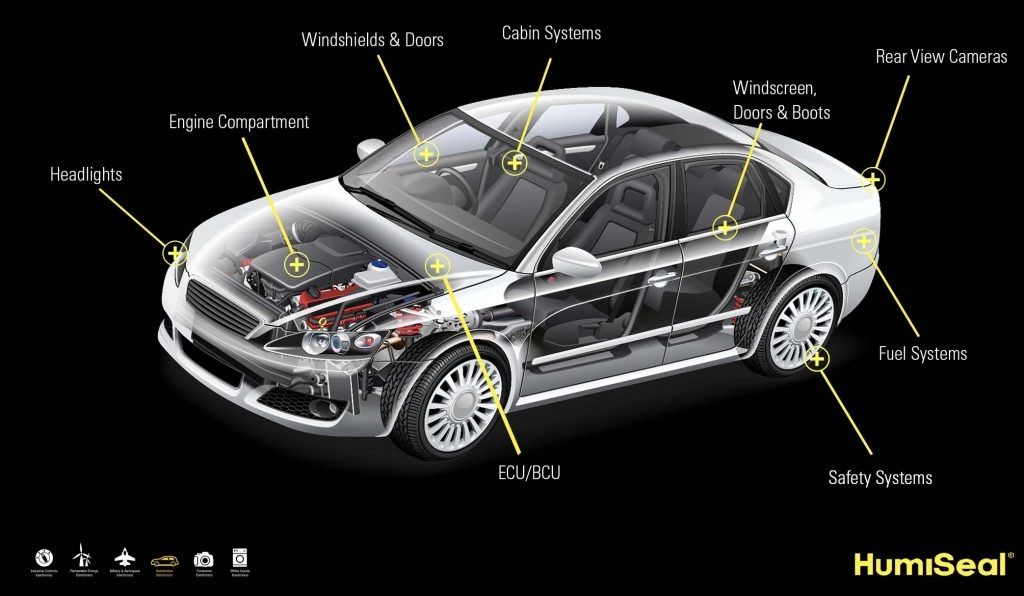

LED-curable conformal coatings are showing promise in applications such as white goods and cars, where high throughput combined with low energy and maintenance requirements is critical.

These companies have also started to emphasise the use of Green, environmentally friendly materials wherever possible. LED conformal coatings have the potential to play a part in this green evolution.

What makes them sustainable?

The use of LED light sources to cure conformal coatings has the potential to be a greener alternative to solvent-based and conventional UV-cured coatings.

Compared to solvent-based coatings, LED curables are:

- Made entirely of solids

- Less bulky in terms of packaging and delivery

- Less energy-intensive than thermal drying ovens and contain little to no VOCs

As compared to conventional full-spectrum arc or microwave UV curing, LED curing needs:

- Less energy

- Less frequent light source maintenance and replacement

- Fewer potentially dangerous wavelengths — There is no need for UVC, and there is no danger from ozone

The UV40 Range

HumiSeal, a pioneer in conformal coatings and electronics safety, has launched a new LED-curable variant of the industry’s most common UV40 coating This LED-curable conformal coating has many of the advantages associated with LED-curable materials, as well as a range of advantages tailored specifically to the demands of PCB protection:

- Tack-free cure under LED UV light at 385 or 395nm

- Low viscosity for film coater selective application

- Secondary moisture cure for unexposed areas

- Superior flexibility, chemical and moisture resistance

- Fluoresces under UV light for inspection

Applications

LED-curable coatings are appropriate for almost all traditional conformal coating applications. Their lower energy requirements (estimated at 30% to 70% less than arc or microwave systems), minimal maintenance requirements, and short cycle times make them particularly useful in some applications, such as:

- Automotive PCBs due to their high volumes and energy requirements

- White goods such as refrigerators, washers, and dryers

- HVAC control boards

- Electronic vehicle applications including power and safety controls and autonomous driving devices

ConRo Electronics, as a supplier of all major types of conformal coatings, will provide you with an impartial approach to assessing your application and operation.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivaled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.