How do I remove flux after soldering the PCB board?

Published date: 17 November 2021

Flux is a chemical cleaning agent used in the soldering of electronic components onto PCBs. Its purpose is to remove oxides and impurities from the board. Using flux improves the solidity of the soldering joints.

The main downside to the use of flux is that it leaves residues on the boards. It is essential to remove these residues after soldering.

Why is it important to remove flux?

Flux residues are acidic. They can corrode the components and damage the PCB over time. Keeping circuit boards clean is especially important for electronics used in high technology sectors, such as medical and aerospace.

Some fluxes are “no-clean”. This means they should require little or no cleaning after application. However, residual no-clean flux can reduce the adhesion of conformal coatings. So, it is best to clean flux residue whenever possible.

How to remove flux with isopropyl alcohol

Rosin flux is the most commonly used in electrical soldering. Flux residue can be cleaned with an isopropyl alcohol (IPA) solution. The solution should be above 90% proof.

Always use latex gloves and goggles when working with isopropyl alcohol. Make sure the working area is well ventilated.

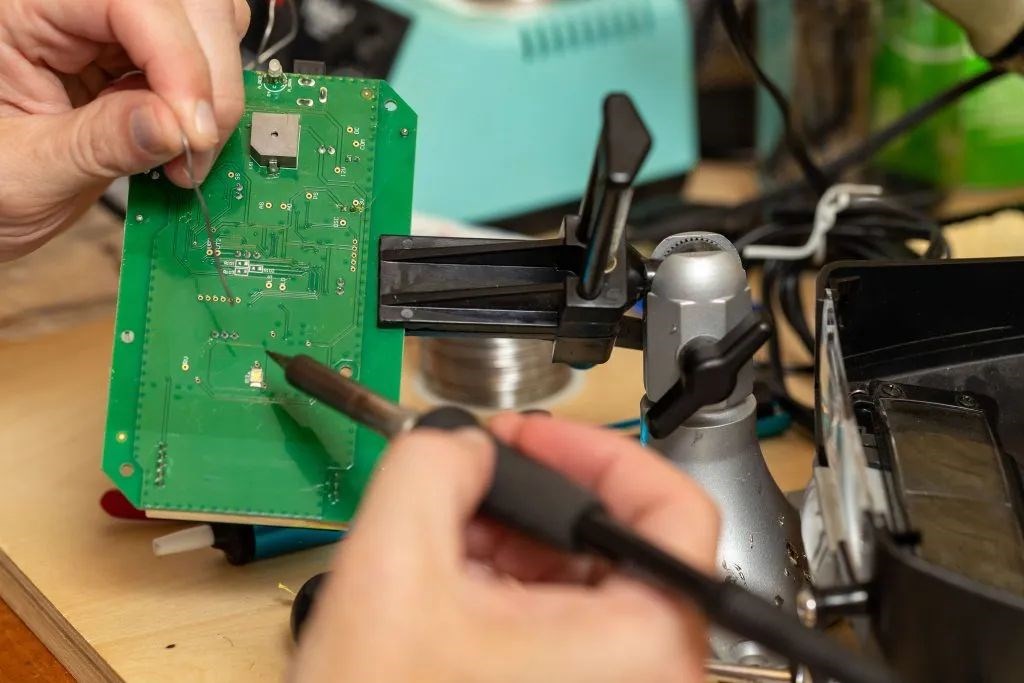

1. Use a clean brush. The brush should be flexible and soft. You can use a toothbrush or an acid brush.

2. If you have a sprayer, you can use it to spray the alcohol solution on the soldered board.

3. Dip the brush in alcohol. Begin cleaning. Use gentle pressure, to avoid breaking the solder joints.

4. Wipe off the board to remove excess solvent. You can use a dry, clean rag or even toilet paper. Don’t wipe with anything that could leave fibers and lint on the PCB.

How to remove flux without using alcohol

Isopropyl alcohol is a good choice for removing flux because has fewer chemicals in it then other PCB cleaners. It’s also cheap, and evaporates quickly. However, it can damage some electronic components. You might want to use a specialised product instead.

Surclean, for instance, offers a line of effective flux cleaners. These products are slower drying and more powerful than IPA. They are also safe to use on most surfaces. The slow evaporation allows more time to remove residues.

You can apply a flux cleaner by spraying. Then, remove the flux residue with a brush, like you would do when using an alcohol solution. Repeat spraying to wash the “spent” material off the PCB. If needed, apply warm air to dry.

How to remove water-soluble flux

Water-soluble flux is an aggressive cleaner. It provides excellent soldering results, but at a cost. Its residue is very corrosive and needs to be completely removed.

Water-soluble flux is designed to be washed off with hot water. A saponifier can be added to help the removing process. Saponifiers are alkaline. They react with the acid residue on the board to form a soap and glycerin. This makes it easier to wash the flux away in hot water.

Conro Electronics offers a wide choice of IPA products and flux cleaners from major manufacturers such as Surclean and Ambersil.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.