What is the best conformal coating?

Published date: 03 February 2022

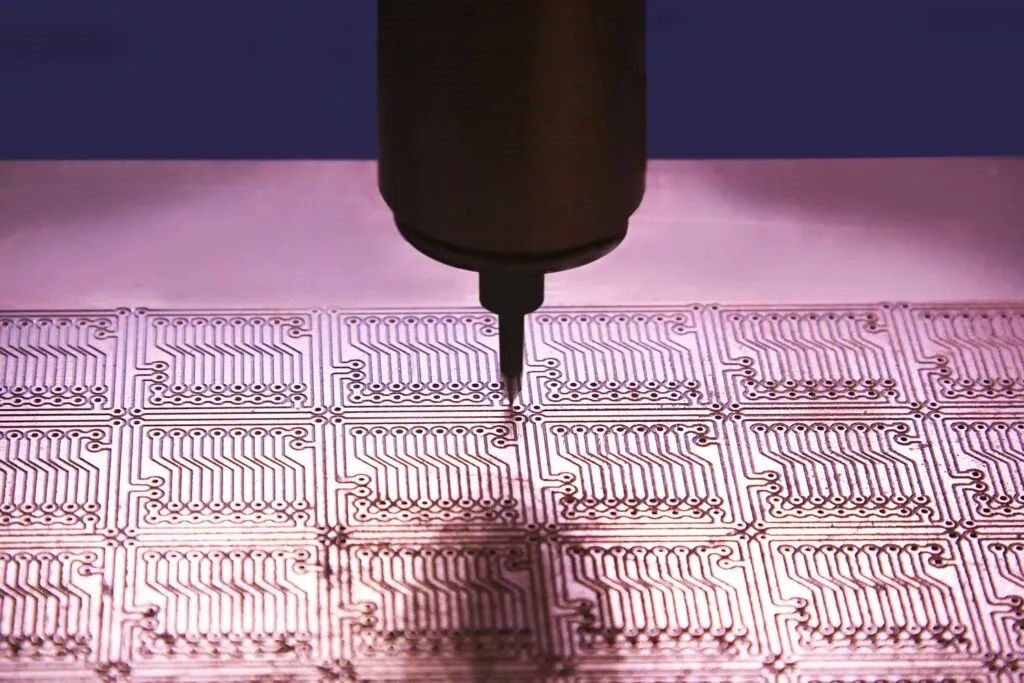

A conformal coating is a thin film which conforms to the shape a printed circuit board. Conformal coatings assure protection from corrosion and external conditions. They also provide electrical insulation. A number of materials can be employed to this purpose.

But what is the best conformal coating? As we will see, each type has different features, strengths and weaknesses. Choosing the best one depends on your specific needs.

Types of conformal coatings

There are five main categories of coatings.

- Acrylic: These coatings provide low-cost general protection. They are especially easy to remove. This makes rework and repair practical and economical. Of course, it also means acrylic coatings are vulnerable to most solvents.

- Silicone: These coatings offer the best protection against temperature extremes. They also resist moisture, chemicals and vibrations. However, silicone coatings provide poor protection from abrasion. This is due to their rubbery texture.

- Urethane: These coatings are best suited for harsh chemical conditions. They are also affordable and flexible. Urethane coatings resist abrasion and are very difficult to remove. The main downside is their long cure times (up to 30 days).

- Epoxy: These coatings are hard and rigid. They offer the best resistance to mechanical wear. Epoxies also have great chemical and moisture resistance. However, they should not be exposed to temperature extremes or heavy vibrations. Such conditions are likely to result in shrinking and cracking.

- Parylene: These thermoplastic coatings are ultra-thin. They provide the best protection against solvents, extreme temperatures and moisture. Parylene conformal coatings are very reliable. On the other hand, they can only be applied by vapor deposition. This requires the use of specialised equipment.

How to select the right conformal coating

There are many options to choose from when it comes to conformal coatings. You should always keep your functional requirements in mind. What kind of environment must the coating withstand?

For example, indoor electronics do not require strong protection. A simple acrylic conformal coating that protects against contaminants and surges is enough. If you are looking to protect a PCB from harsh environments, you will need a different coating. A circuit board installed inside a vehicle or aircraft requires a silicone or urethane coating. Perylene will protect a PCB from extreme humidity, and so on. Evaluate the pros and cons of each material and match them with your requirements.

To meet your needs, you may require a certified product. Certifications distinguish general purpose varnishes from specialised conformal coatings. The two major certifications are IPC-CC-830B and UL746E. Both of them involve a wide range of tests.

Conro Electronics offers a wide choice of conformal coatings for electronics and are Humiseal’s UK / Ireland Sales & Technical Partner.

We’ll show you how to improve product reliability while increasing performance and lowering costs. Our team of technical support specialists will provide your company with dependable global supply, unrivalled efficiency, and superior technical support.

Feel free to contact us on 0208 953 1211 or send us an email to info@conro.com

Comments

There are currently no comments, be the first to comment.